X ray transparent due to its low.

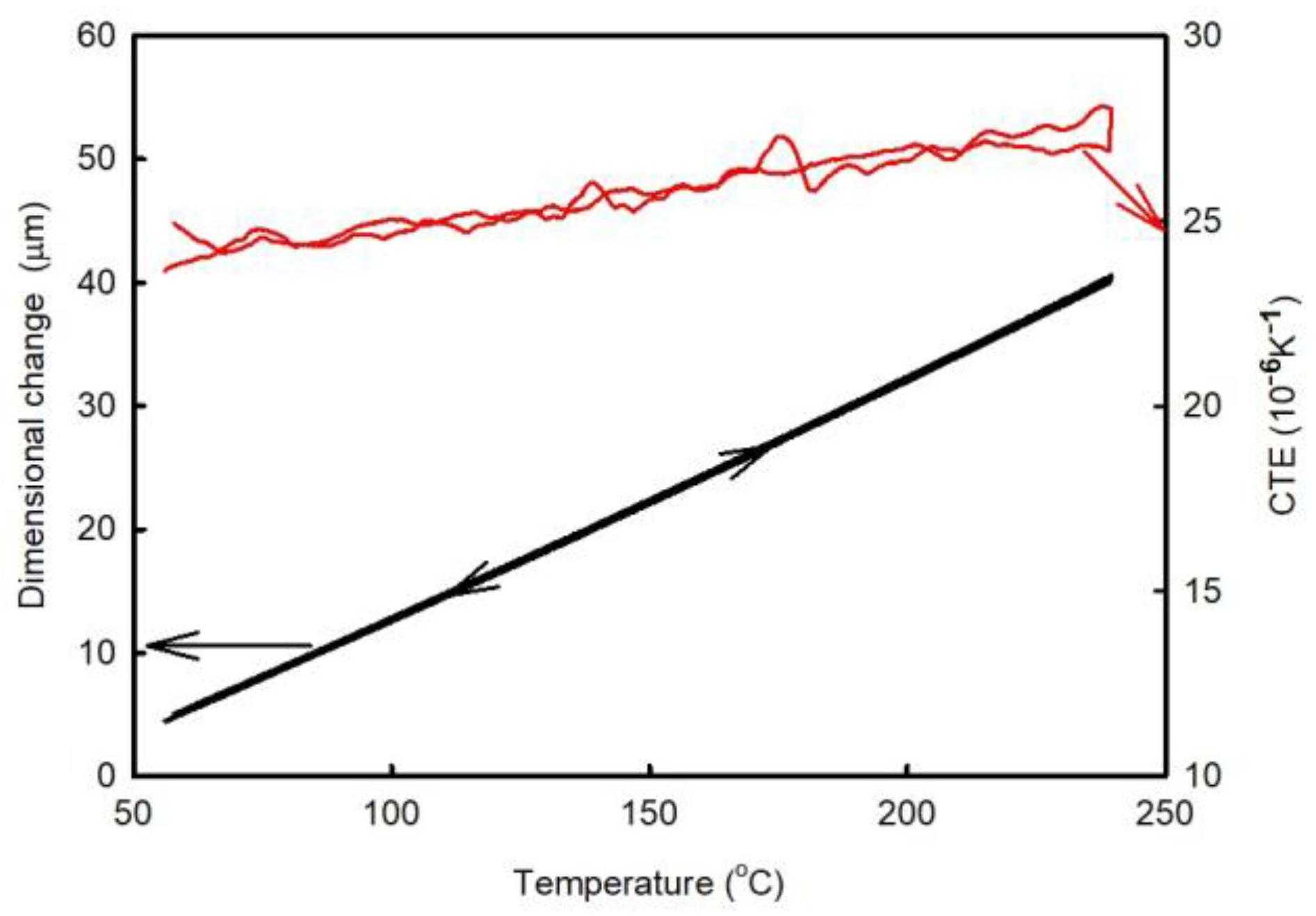

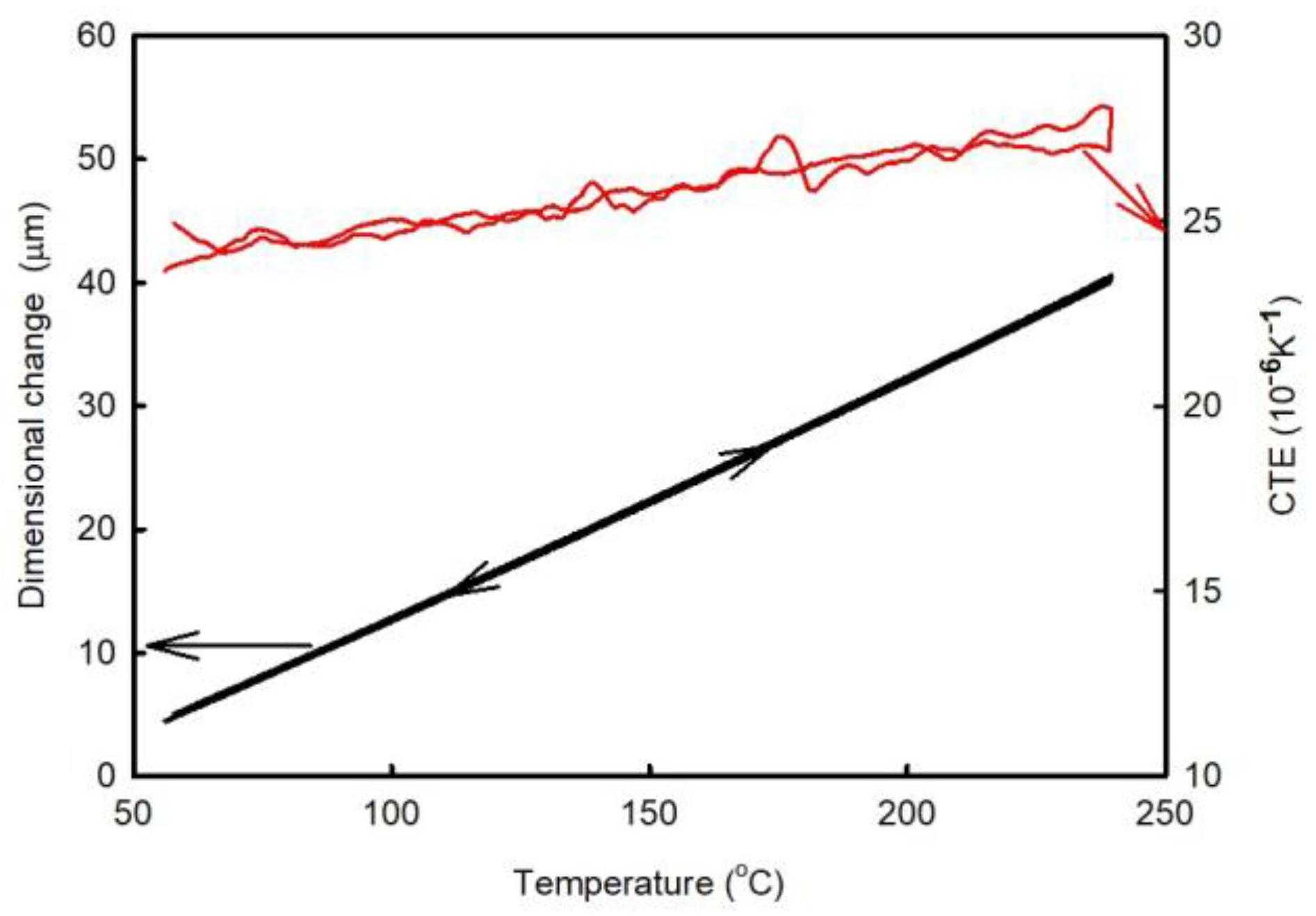

Coefficient of thermal expansion carbon fiber laminate.

Experimental validations are first realised on isotropic metallic tungsten fiber.

On the basis of lamination theory a quasi isotropic fiber metal laminate fml with a near zero coefficient of thermal expansion cte and high specific modulus was designed using pitch based carbon fiber reinforced plastic cfrp prepreg and stainless steel sst.

This paper presents results for the coefficient of thermal expansion cte of fully cured carbon fiber epoxy composites that was obtained in three principal directions using a thermomechanical.

Take the automobile industry as an example automotive fuel consumption to 60 car body weight 10 per weight the fuel consumption.

The thermal expansion coefficient of carbon fiber is less than that of metal.

Thermal deformation coefficient of thermal expansion carbon epoxy formulation of ctes for temperature variation introduction carbon fiber reinforced composites are widely developed and used as structural materials of the modern aircraft and spacecraft because of their high specific strengths moduli and design flexibilities.

The advantages of graphite composites are.

Aluminium and carbon have been tried but the mixture forms a galvanic couple causing corrosion.

Material properties material properties for gases fluids and solids densities specific heats viscosities and more.

High specific stiffness stiffness divided by density 2.

For this reason copper has been combined with carbon fiber graphitic materials to create a material with significantly smaller coefficient of linear thermal expansion.

Abs pipes pressure ratings pressure ratings of.

Extremely low coefficient of thermal expansion cte 4.

Thermodynamics effects of work heat and energy on systems.

A composite laminate has been developed that has a coefficient of thermal expansion identical to that of schott d263 glass.

Copper has a coefficient of 16 6 10 6 m m k while carbon fiber can be as low as 0.

It has been used instead of metal materials in many fields.

Recently the cfrp laminate layup 0 30 90 30 0 4s composed of poly cyanate resin and pan based carbon fibers was designed with the cte being approximately zero.

It also has four times the strength of steel and the weight of 1 4 steel.

Carbon fiber reinforced plastic cfrp laminates are used for structures of space satellites because of their high stiffness and low coefficient of thermal expansion cte.

High specific strength strength divided by density 3.

Also the material thickness and fiber orientations can be optimized for each application.

In this study the measurements of cte are presented at very high temperatures up to 2500 k.