The properties like strength ductility malleability hardness wear resistance and thermal conductivity have varying magnitude for each of metals polymers and ceramics.

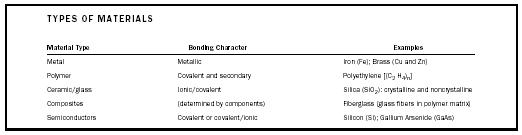

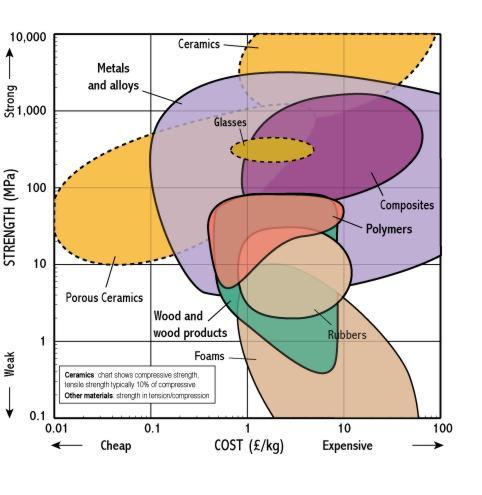

Comparison of metals ceramics and polymers.

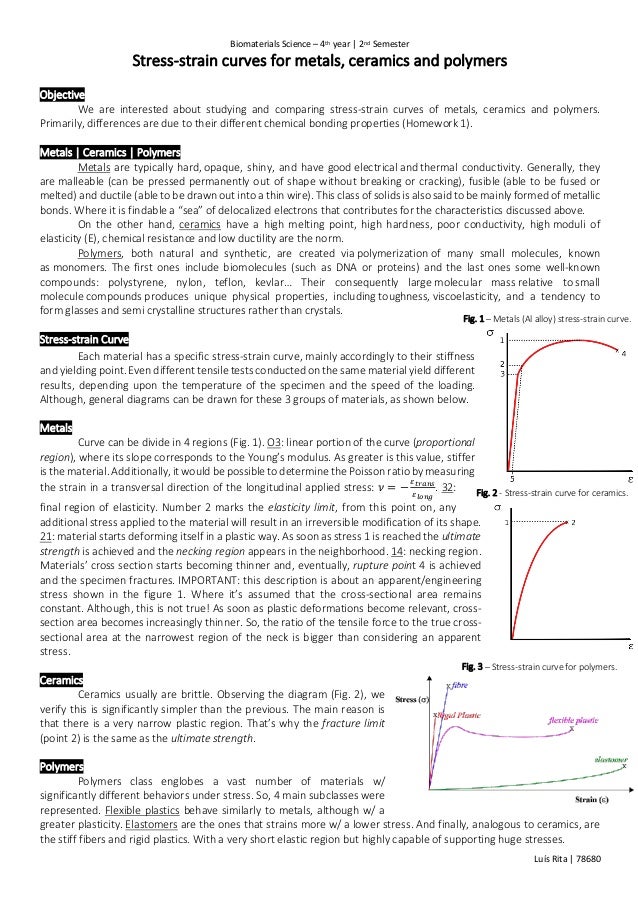

Stress strain curves for metals ceramics and polymers objective we are interested about studying and comparing stress strain curves of metals ceramics and polymers.

Majorly composed of al 2 o 3 aluminum ceramic is a dense ceramic material with excellent thermal and electrical resistance properties.

Many new combinations include ceramic fibers in metal or polymer matrix.

Different materials have different properties.

The key difference between polymers and metals is that the polymers are lightweight than the metals.

Fiberglass a combination of glass and a polymer is an example.

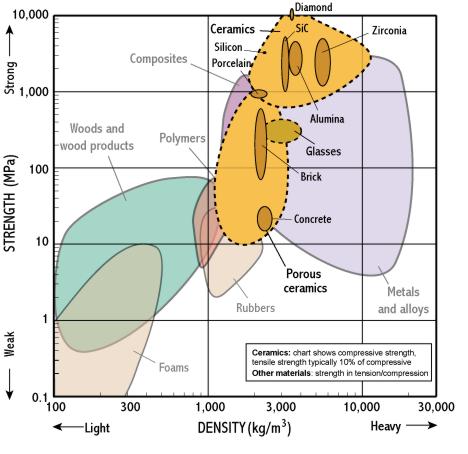

The distortion phenomenon under load in ceramics is also reasonably small as compare to metals.

Ceramics are hard and strong but brittle.

The higher hardness of ceramics explicates that these are slighter disposed to wear out and can be more durable that steel ball bearings.

Moreover the strength to weight ratio of polymer materials is higher than that of metals.

Metals many similar properties but alloys have very variable strength and melting point 2.

Polymers are strong and tough and often flexible.

Composite materials combine two or more materials.

The metals polymers and ceramics not only have a different physical appearance but also have variations in mechanical properties.

Metals are a material made up of metallic elements that are bonded metallically like common alloys.

Concrete and plywood are other familiar composites.

Primarily differences are due to their different chemical bonding properties homework 1.

A comparison of four groups of materials.

However metals have a lustrous appearance and high thermal and electrical conductivity.

Copper is a soft malleable and ductile metal with high thermal and electrical conductivity.

Normally the components can be physically identified and exhibit an interface boundary between one another.

Polymers plastics properties very dependent on whether thermosoftening or thermosetting.

Polymers can experience fatigue under a repetitive loading.

It is also resistant to corrosion and permeable for microwaves.

They are generally softer than metals and ceramics and unlike metals and ceramics polymer melting occur over a range of temperatures instead at a specific temperature.